Conventional sintering generally adopts conventional heating method which is the most commonly used sintering method in ceramic material production at present.

Ceramic sintering press force.

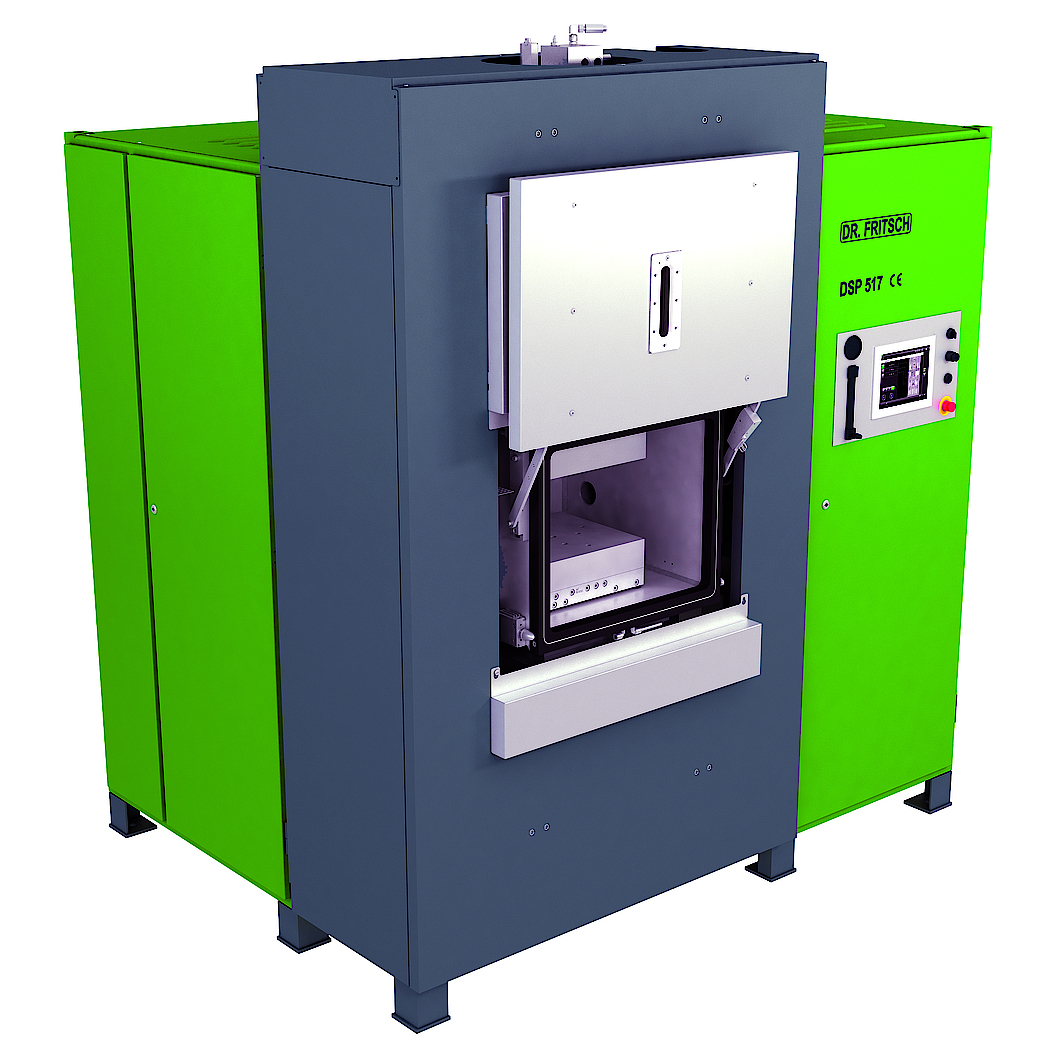

This hot sintering press ryj series is controlled by plc and can save 100 groups preset pressure and temperature curves.

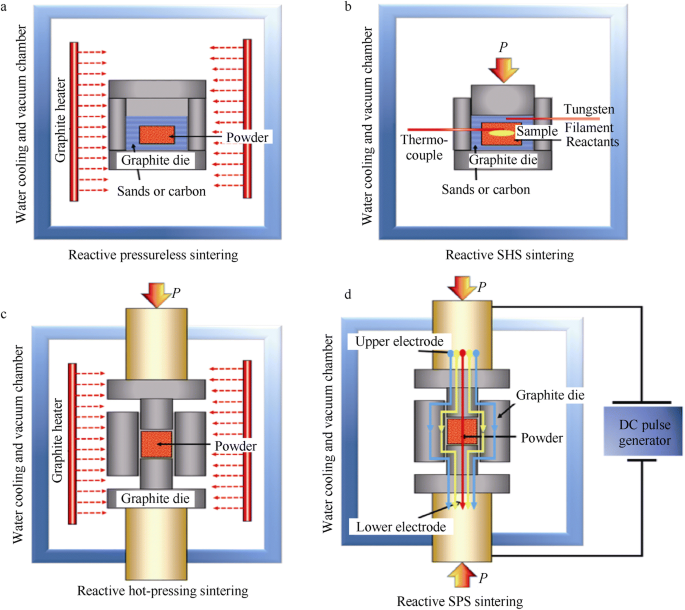

Reaction sintering reactive sintering is limited to a few systems.

Force for industrial powder manufacture typically varies between 10 000 lbs in 2 70 mpa and 120 000 lbs in 2 800 mpa.

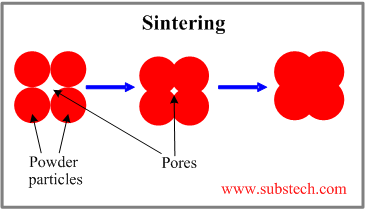

The driving force of sintering appears as differences in bulk pressure vacancy concentration and vapor pressure.

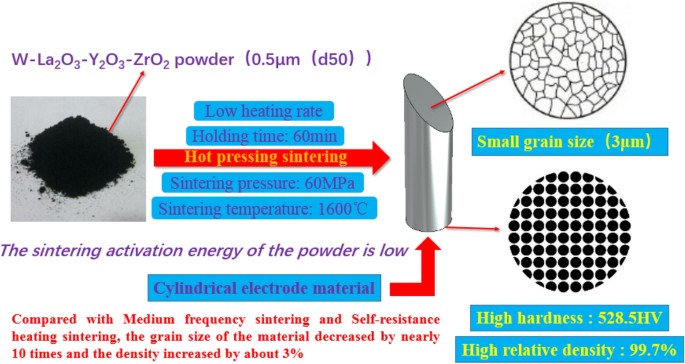

Once the ceramic powder has been compacted and green machined if required the powder compact is usually around 50 of its final theoretical density.

It is widely applied for various diamond product sintering.

Sintering of ceramics provides the only comprehensive treatment of the theories and principles of sintering and their application to the production of advanced ceramics with the required target microstructure.

The driving force behind sintering is largely determined by neck geometry and size.

Mostly using the vacuum sintering furnace to process.

Compaction and sintering of a ceramic seal.

With the latest update ryj series have better performance on saving power 25 decrease.

Sintering or frittage is the process of compacting and forming a solid mass of material by heat or pressure without melting it to the point of liquefaction.

Sintering happens naturally in mineral deposits or as a manufacturing process used with metals ceramics plastics and other materials the atoms in the materials diffuse across the boundaries of the particles fusing the particles.

Silicon nitride silicon oxynitride silicon carbide etc.

Stemming from the author s bestselling text ceramic processing and sintering this book includes additional material selected from many sources providing a single comprehensive.

Full densification is achieved by sintering at temperatures up to 1800 c.

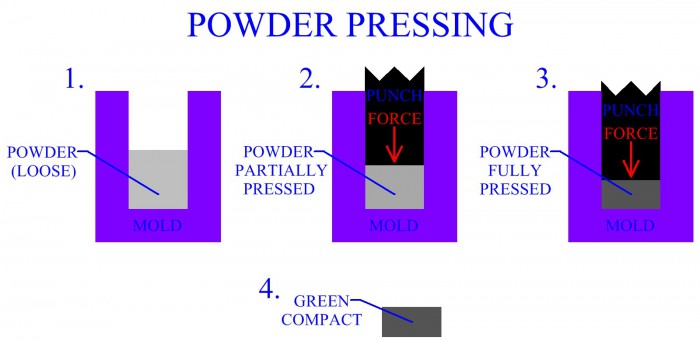

Pressing force is a function of pressure over the area of the part perpendicular to the direction of pressing.

Powder metall 39 6 2003 27 34 link.

An examination of the geometrical relationship around the neck is first needed.

The driving force of sintering process is reduction of surface energy of the particles.

Modeling and experimental response int.

Usually the press is vertical in this case the horizontal plane of the part would be considered.

Optimizing press tool shapes by numerical simulation of compaction and sintering application to a hard metal cutting insert modelling and simulation in materials science engineering 11 3 2003 381 400 link.

Sintering sintering is the process by which a powder compact is transformed to a strong dense ceramic body upon heating sintering could eliminate most pores in porous green body and compress residual pores and bring grain growth and improve binding among grains driving force for sintering.