According to the industry group that decides whether a tile is porcelain or ceramic everything boils down to whether the tile can meet a set of highly controlled water absorption criteria.

Ceramic tile grades vs pei.

Grade 3 tiles are the thinnest 1 4 inch thick and.

Here is a link to all of our full body porcelain tile.

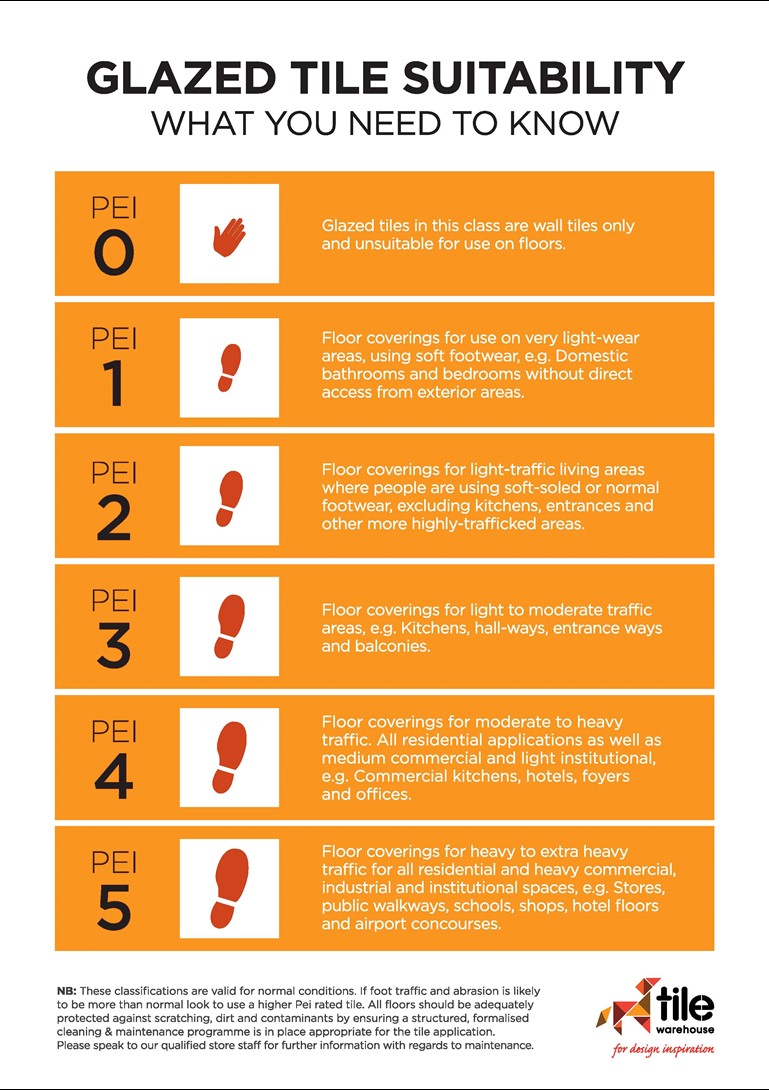

Pei wear rating porcelain enamel institute pei wear rating indicates tile s resistance to abrasion.

The best type of tile would be a full body darker porcelain tile with a pei rating of 4 or 5.

Pei ratings act as a kind of shortcut to figure out where the tile can be installed.

Here are the pei tile ratings so you can use them for your next tile purchase.

Grade 2 reflects that some imperfections exist but the tile still is usable on walls or floors.

It does not measure the fracture strength of the entire tile nor does it offer any rating of the slip resistance of the tile.

Again a great product for wall tiles but it.

For example tile with a pei grade of 1 which is the lowest can last for years and look gorgeous when it s installed as a decorative wall tile.

Tile that experiences much foot traffic should be harder and denser than than that receives no foot.

Grade 3 tiles are not allowed on floors.

Reflects suitability for floor traffic.

Porcelain enamel institute pei chart pei rating helps to classify the durability and functionality of these surfaces with the following system.

It s really only suitable as a wall tile.

This is the weakest of all standard grade ceramic tiles.

Pei porcelain enamel institute ratings help you determine the hardness and durability of tile.

This is crucial because not all tile can be used in all areas.

Porcelain tile floors can hide scratches because they are the same color throughout.

Perhaps more important though is porcelain flooring s ability to avoid most scratches altogether.

Floor tiles are allowed on walls.

The pei categorization primarily defines the hardness and durability of the various ceramic products that are tested.

Full body is when the tile is the same color throughout and it s better to go with a darker tile in case there are any leaks.

The porcelain tile manufacturing process.

This rating is for glazed tiles designated for use on walls only.

These tiles are approximately 1 2 inch thick.

Both ceramic tile and porcelain tile usually receive a surface glazing that makes them hard to distinguish.

Bit drilling into a tile pei i and ii.

Both strong and durable porcelain tile wears like iron and is an excellent choice in areas that see a lot of foot traffic.

Ceramic tile and porcelain tile have much in common in how they are manufactured and used.

This is best for light traffic areas.

Thinner tile designed for walls not floors.